I can’t believe that is’ been May since I last posted, but worse – I cannot believe I never posted anything about my 3D printer build. That’s terrible!

Well, to correct the omission, onward.

In January 2016 I started building a 3d printer with the encouragement from a colleague at Athabasca University. He had built one and thought I’d love doing it as well. He was an immense help, first giving me a detailed list of what to purchase from which ebay vendor, then actually printing the key plastic parts on his printer and sending them to me.

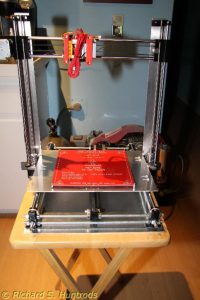

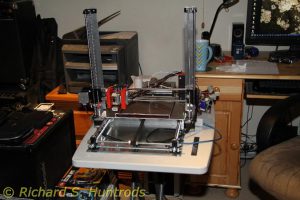

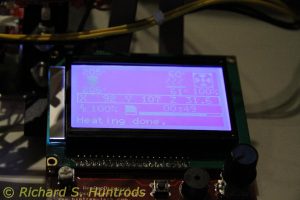

The idea was to custom build a Prussia I3 printer rather than buy a kit. Kits were/are costly, and don’t always use the best parts. By purchasing exactly what you want, you can customize the build as well as optimize the quality. In the end I bought about $350 worth of stuff from ebay, including rods, bearings, heated bed, stepper motors, extruder and all the electronics. A note about the electronics – the Prussia I3 can use many boards, but we used the RAMPS 1.4 which includes the arduino mega and an LCD control panel. The RAMPS has controllers for all the stepper motors as well as the extruder and heated bed. It runs off a slightly modified ATX power supply as it needs 12V at 25A.

I also bought other parts locally, such as threaded rod, nuts and washers, as well as some aluminum plate for the frame and beds. Here I ended up spending about $225, so my total build cost was $575 (Canadian funds) including shipping and taxes.

The hard part initially was waiting. Buying this stuff off Ebay means Hong Kong, which in turn means 2 weeks to 1+ months delivery wait times. It gets pretty difficult to keep enthused while you check the post each day.

Finally in Feb or so most of the parts were in, and I could start. There are a lot of really good build videos and instructions on the internet, so I started with those.

By March I had the basic Y axis and X asis frames build, and there I stalled. My colleague used wood for his base and support structures, but I didn’t have the right wood and just could not get enthused about wood for this build. So I put it all away in a box for safekeeping, and there it sat until late May of 2017.

Then I had an epiphany. I would build the frame from aluminum plate, as it’s easy to work with, relatively inexpensive and easy to get and have cut. I checked the built y axis against a large sheet of cut aluminum plate, and it fit perfectly. From there it began anew.

First I made sure the Y axis was true, then glued the feet to the aluminum plate with epoxy. Once that had cured, I started to design the vertical support system for the X and Z axes. Gradually it came together. Of course, the design/test/correct process means most of the holes become slots, but that’s not a big problem.

Once I got going, things really progressed quickly. The biggest problem became a lack of M3 bolts in various sizes. I’d originally bought a few specific sizes from an Ontario mail order outfit, but they were pricey and selection poor. Finally in June 2017 I bit the bullet and ordered a 440 variety pack from Hong Kong, figuring a month wait. To my surprise, it came in a week and I was back in business with even more renewed vigor.

By the fist week in July I had the printer complete, and started testing. There I hit some major snags. All the build instructions said “the kit comes with firmware loaded”. Well, I didn’t use a kit, so there was no firmware. Worse, my colleague from AU no longer worked there, and it took some time to reconnect. Finally I did, and with a few tips from him I was able to find the arduino software that compiles to the firmware that drives the printer.

This highlighted a further problem: the firmware has about a zillion parameters that must be set for your particular printer. Some aren’t critical, but others (like stepper motor settings) are essential. Fortunately the default parameters are pretty close for most things, and there are ample comments and options to get things up and running without too much bother.

Then there’s the ancillary software. To build a model, the printer needs instructions. The process is simple in theory. You take a 3d model and load it into a ‘slicer’ program which creates the actual instructions to drive the printer. It’s all very cool and open source, with the ‘gcode’ file being completely human readable. You can even manually tweak the file if you want. The problem yet again is the slicer program has dozens of options, most of them critical for a good print.

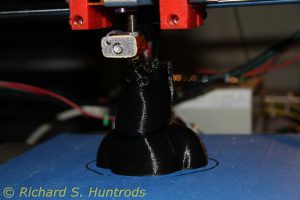

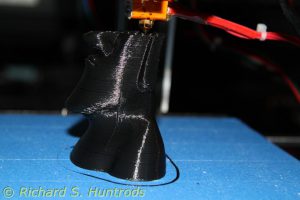

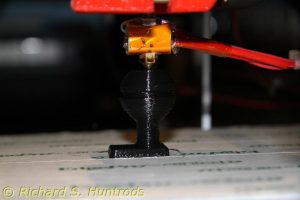

Ultimately I got most things running by July 10, with the exception of the extruder. No matter what, it just created puddles of goo that it would then plow through while trying to print. After much internet searching, I found one document that discussed “extruder calibration”. Now I’d already calibrated the X, Y and Z stepper movement, which turned out to be perfectly aligned with the firmware default stepper rates. Of course I figured the supplied default would be correct for the extruder as well. However, puddles of goo said otherwise, so I calibrated the extruder. You simply make a mark on the filament, extrude a set amount and see if the actual movement matches the desired movement. To my surprise, I was running 5x what I wanted. Fortunately, with all those parameters in the firmware source, it was quick work to enter a corrected extruder parameter, and another test showed that I was now spot on.

With that, I printed my first 3d object on July 10, 2017 – a 20mm cube using PLA filament. When cooled, it was 19mm on every side, straight and true, so I am very happy with the operation of my 3d printer.

Later that night I printed a 1inch ball mount for my underwater video light, and it’s also turned out perfect.

Here’s a link to a video of the printer creating the cube: https://youtu.be/h1DfgUolt5A